Our products are applied in many fields.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, farms, Construction works , nylon sleeve coupling

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Body material:

-

45EPG is willing to cooperate sincerely and develop commonly with friends!# steel

- Surface Treatment:

-

Blackening

- Length:

-

Customer Made

- MOQ:

-

1 Set

- Certification:

-

ISO9001:2008

- Packing:

-

Wooden Box

- Sleeve Material:

-

Nylon

- Materia:

-

45#stell

- Color:

-

Black

- Bore type:

-

Pilot Bore + Finished Bore

We designed, especially for our customers, a protective cone which is flexible and enables easier handling while coupling the PTO on the tractor or working machine. The flexible cone offers additional comfort when coupling the PTO, because you can get a good grip in the limited shaft space.

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- standard export packing and wood pallets packing

- Port

- TIANJIN

-

Lead Time

: -

Quantity(Units) 1 – 500 501 – 2000 >2000 Est. Time(days) 15 25 To be negotiated

Online Customization

The Series B EPG x right angle worm geared motors and reducers provide a highly flexible and compact solution to meet the low to medium power range. With power capabilities up to 20HP and maximum output torque capacity of 5,000 lb in., the Series B can provide design flexibility with lasting performance. The Series B benefits from more than 200 years of cumulative experience in the design and manufacture of high quality mechanical power transmission solutions. With features like our patented motor connection and the unique Swift Kit concept, Series B is the answer for your right angle drive requirements.

Product Description

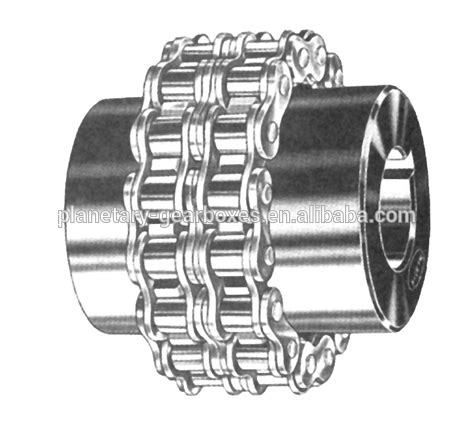

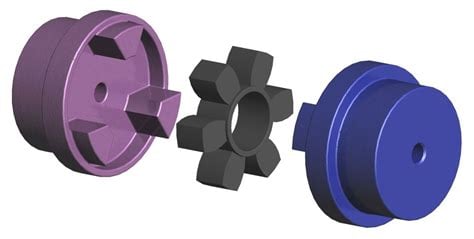

A gear coupling is a mechanical device for transmitting torque between two shafts that are not collinear. It consists of a flexible joint fixed to each shaft. The two joints are connected by a third shaft, called the spindle.

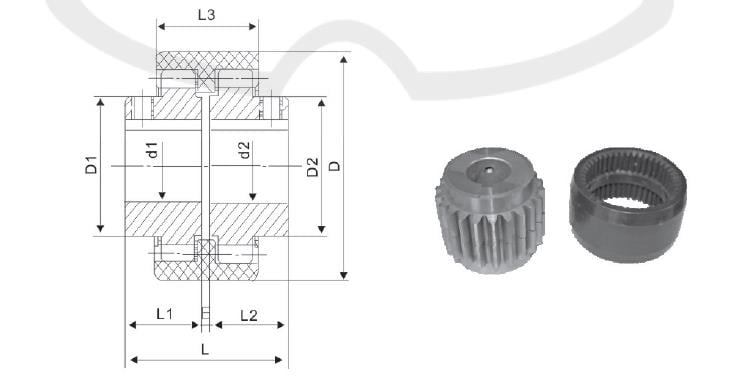

Each joint consists of a 1:1 gear ratio internal/external gear pair. The tooth flanks and outer diameter of the external gear are crowned to allow for angular displacement between the two gears. Mechanically, the gears are equivalent to rotating splines with modified profiles. They are called gears because of the relatively large size of the teeth.

Gear couplings and universal joints are used in similar applications. Gear couplings have higher torque densities than universal joints designed to fit a given space while universal joints induce lower vibrations. The limit on torque density in universal joints is due to the limited cross sections of the cross and yoke. The gear teeth in a gear coupling have high backlash to allow for angular misalignment. The excess backlash can contribute to vibration.

Gear couplings are generally limited to angular misalignments, i.e., the angle of the spindle relative to the axes of the connected shafts, of 4-5°. Universal joints are capable of higher misalignments.

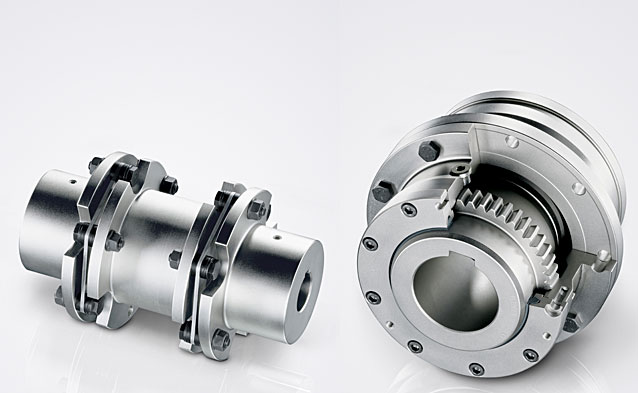

The internal gear-shaped elastic coupling is the latest product in China and has been widely used in foreign countries. This product is designed by the Jinan Foundry and Forging Machinery Research Institute of the Machinery Commission. It is suitable for flexible transmission between shafts and allows for larger shafts. Radial displacement and angular displacement, and has the advantages of simple structure, convenient maintenance, easy assembly and disassembly, low noise, small loss of transmission efficiency, long service life, etc., and is popular among users. The shaft hole type has a cylindrical shape (Y), a conical shape (Z), and a short cylindrical shape (J). The shaft hole and keyway are processed according to the national standard GB3852-83 “Coupling shaft hole and keyway form and size”. The working temperature is -20 ~ +70 °C.

The semi-coupling is made of precision casting, cast iron HT20-40, cast steel ZG35II, shaft hole and keyway are made by drawing. The inner toothed coupling elastic body jacket can be made of various hardness synthetic rubber grease rubber according to user requirements; Reinforced materials such as cast nylon elastomer. In order to meet the needs of various mechanical renovations and the introduction of spare parts for equipment, our company can provide internal gear-shaped flexible couplings with complete specifications and specifications, and can accept non-standard orders according to user needs.

Advantages of EPT gear coupling

1. Lowest price based on large scale production.

2. High and stable quality level.

3. Widely used in various mechanical and hydraulic fields.

4. Compensation for axial, radial and angular misalignment.

5. Convenient axial plugging assembly.

6. No brittlement at low temperature.

7. Good slippery and frictional properties.

8. Resistance to chemical corrosion.

9. Rich experience working with big companies in this field.

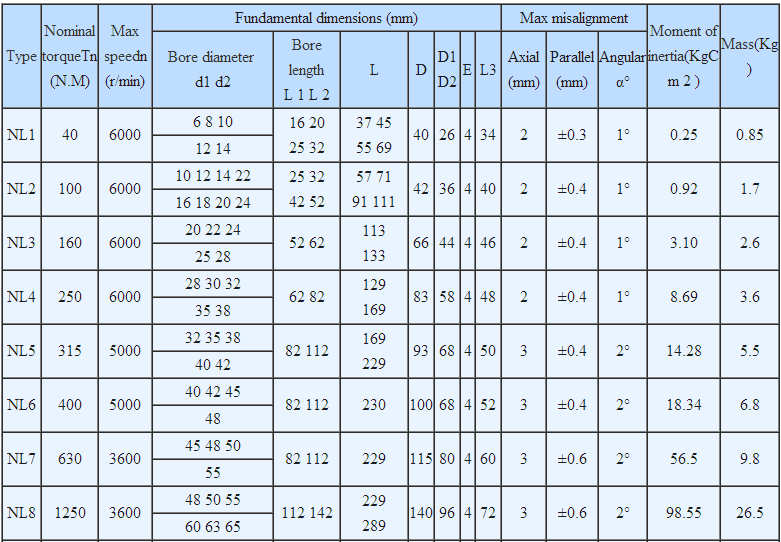

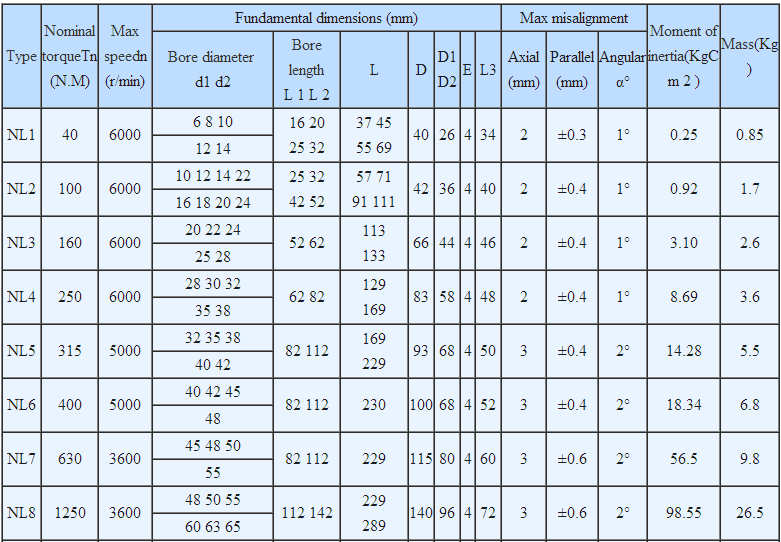

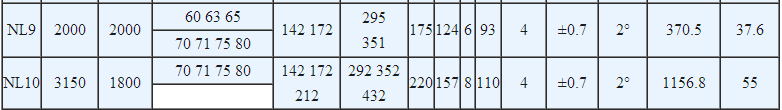

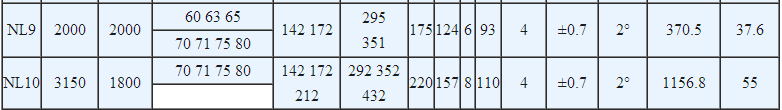

Nylon gear flexible coupling is the latest product,it has been using by abroad,and it is designed by mechanical committee of Jinan Casting forging machinery institute.

Features of NL gear coupling:

1.Absorb parallel,angular and axial misalignments

2.Simple assembly and disassembly

3.Easy maintenance and low noise

4.High tansmission efficiency

5.Long service life

Certifications

Company Information